Recognizing the Capability of Membrane Layer Changes for Individual User Interface Instruments

The performance of membrane switches over stands for a significant improvement in individual interface layout, incorporating effectiveness with aesthetic flexibility. As industries increasingly focus on user experience, recognizing the subtleties of membrane layer switch modern technology ends up being essential.

What Are Membrane Switches?

Membrane buttons are ingenious interface devices that assist in user communication with digital equipment. These flexible elements consist of several layers, including a visuals overlay, spacer, and a published circuit layer. The layout enables for a smooth combination into various electronic devices, improving both the aesthetic and functional aspects of interface.

Membrane switches are frequently employed in a wide array of applications, from household home appliances to industrial machinery and medical gadgets. Their building and construction commonly features a slim account, making them an optimal option for small styles. The tactile feedback offered by these switches can be engineered to meet specific customer preferences, guaranteeing effective communication in between the user and the gadget.

Longevity is an additional substantial benefit of membrane switches, as they are resistant to dust, dampness, and chemicals, which boosts their life-span in requiring atmospheres. In addition, these switches can be personalized in terms of form, size, and graphic style, permitting branding and user-specific features. On the whole, membrane layer switches represent a useful remedy for improving customer experience in electronic tools, incorporating performance with visual appeal in an efficient manner.

How Membrane Layer Switches Job

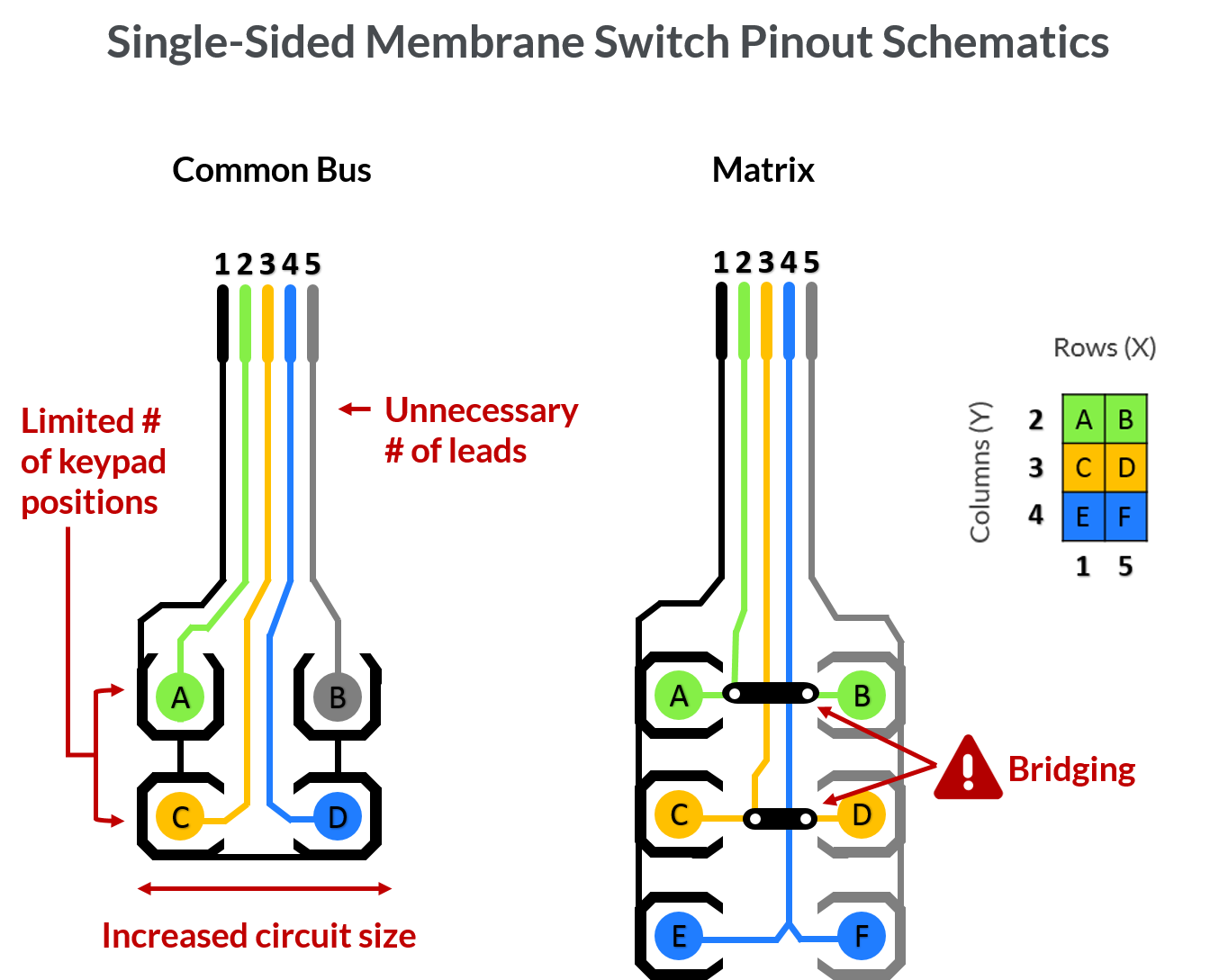

Operating on a simple principle, membrane switches use a split building to sign up customer input efficiently. Each switch includes several layers, consisting of a printed circuit layer, a spacer layer, and a leading graphic layer, which are created to function together flawlessly. When a customer presses the leading layer, it compresses the spacer layer, bringing the conductive components of the circuit layer into contact with each various other.

This call creates a closed circuit, signaling the tool to perform a specific function. The layout allows for various setups, including tactile feedback, which can boost the user experience by supplying a physical sensation upon activation. The materials made use of in membrane layer buttons usually include flexible substratums, such as polyester or polycarbonate, which guarantee resilience and strength versus deterioration.

Key Benefits of Membrane Layer Switches

An additional substantial advantage is their compactness. Membrane buttons are slim and lightweight, which allows makers to save space in their devices without sacrificing performance. This function is specifically beneficial in applications where weight and volume are critical considerations.

Additionally, membrane layer switches are immune to dirt, dampness, and chemicals, improving their durability. This strength prolongs their life-span useful link and minimizes the demand for constant replacements, causing expense financial savings gradually.

Additionally, the tactile feedback given by membrane buttons can be maximized to improve individual interaction. They can consist of attributes such as elevated switches or audible clicks, boosting functionality and user experience.

Applications Across Industries

Individual user interface devices making use of membrane layer switches prevail in a wide range of sectors, showcasing their adaptability and functionality. Membrane Switch. In the clinical industry, membrane layer buttons are integral to tools such as analysis tools and client surveillance systems, where their durability and ease of cleaning are essential for preserving hygiene standards. Similarly, in the automobile sector, these buttons are employed in dashboard controls and infotainment systems, providing a smooth and modern interface for users.

Additionally, the customer electronic devices field benefits from membrane layer switches in home appliances and handheld devices, where compact style and user-friendly user interfaces enhance individual experience. Industrial applications also take advantage of membrane changes for control board in equipment and automation systems, stressing their effectiveness and resistance to rough environments.

In the aerospace and protection markets, membrane switches are made use of in cabin controls and devices, where reliability and efficiency why not try this out under extreme problems are critical. Furthermore, the pc gaming sector progressively includes membrane layer switches in controllers and arcade machines, adding to an engaging individual experience. On the whole, the convenience of membrane changes enables their widespread use across numerous fields, highlighting their significance in contemporary interface layout.

Future Trends in Membrane Switch Over Innovation

In addition, the usage of innovative materials, such as polycarbonate and polyester films, is expected to increase, giving enhanced toughness and resistance to ecological stressors. These materials add to the general durability of membrane layer switches, making them ideal for harsher industrial applications.

In addition, the incorporation of smart innovation, including IoT connection, will certainly enable membrane buttons to communicate with various other tools and systems, facilitating a more interactive user experience. This trend aligns with the growing demand for smart devices across various industries, from healthcare to consumer electronics.

Finally, personalization choices are anticipated to expand, allowing manufacturers to create bespoke solutions customized to details individual needs find more and preferences. These growths will certainly place membrane switches as vital components in the evolution of customer interface modern technology.

Verdict

To conclude, membrane switches stand for an essential improvement in interface technology, supplying a reliable and functional option for diverse digital applications. Their layered building promotes portable layout, while functions such as tactile responses enhance customer interaction. The longevity versus environmental variables additionally solidifies their energy across several industries. As innovations in product science and touch picking up modern technologies continue, the capability and applicability of membrane buttons are expected to broaden, reinforcing their value in contemporary digital devices.